15370980098

15370980098

0513-88711586

0513-88711586

0513-88963966

0513-88963966

xinlaimeng89@163.com

xinlaimeng89@163.com

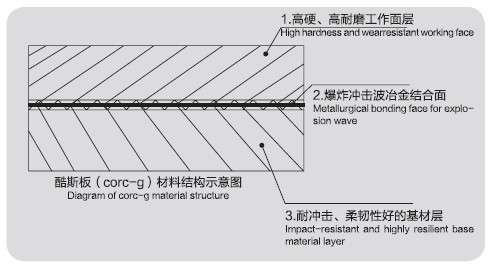

Structure and application:

Materials with high hardness and wear-resistance are selected as working face of corc-g and materials with impactresistance and good resilience are chosen as base materials. Through explosive welding, these two totally different materials are firmly combined together and made into a new high wear-resistant lining plate, which possesses relatively high hardness and wear-resistance as well as relatively good resilience and impact-resistance after thermal treatment.

Corc-g is mainly applied in bearing block the rack wear-resistant plate, working roll and back-up roll of metallurgical hot rolling mill (especially medium plate hot continuous rolling mill). Since there are huge roll impact and roll force when the billet goes into the roll and during working process, lining plates of rack, working roll and back-up roll must possess relatively high hardness, wear-resistance as well as relatively good resilient to resist the impact and force. Corc-g solves this scientific and technological problem.